the power

of innovation

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

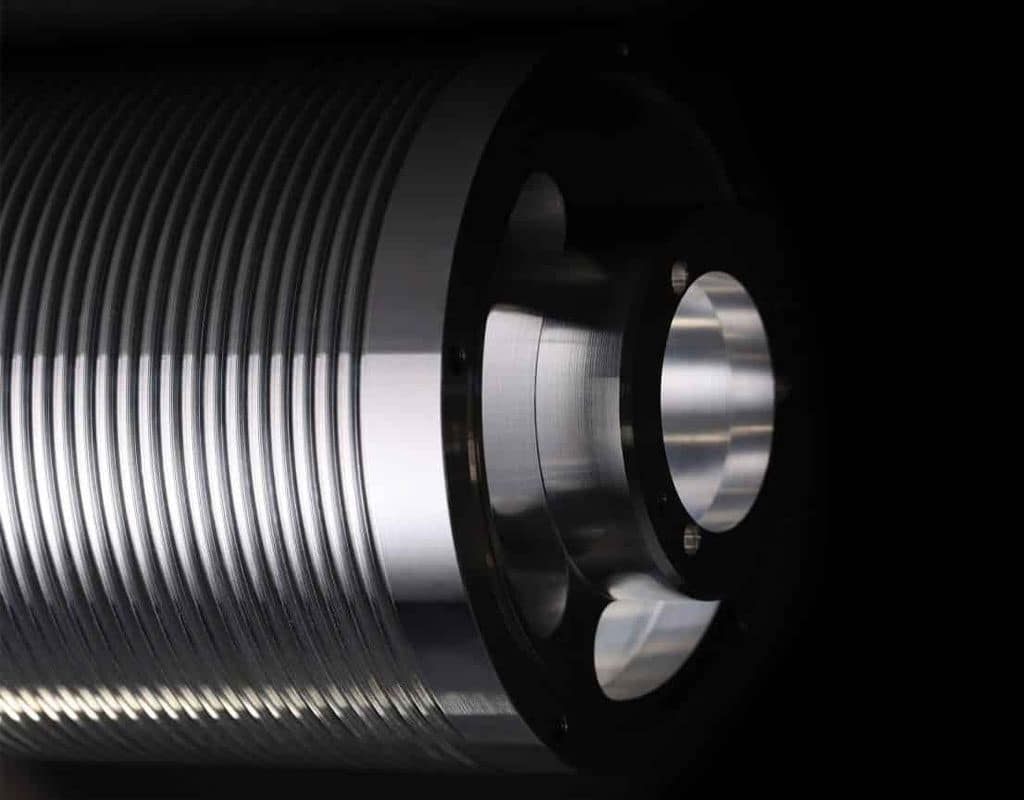

Machine tools

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

Aerospace

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

Aeronautics

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

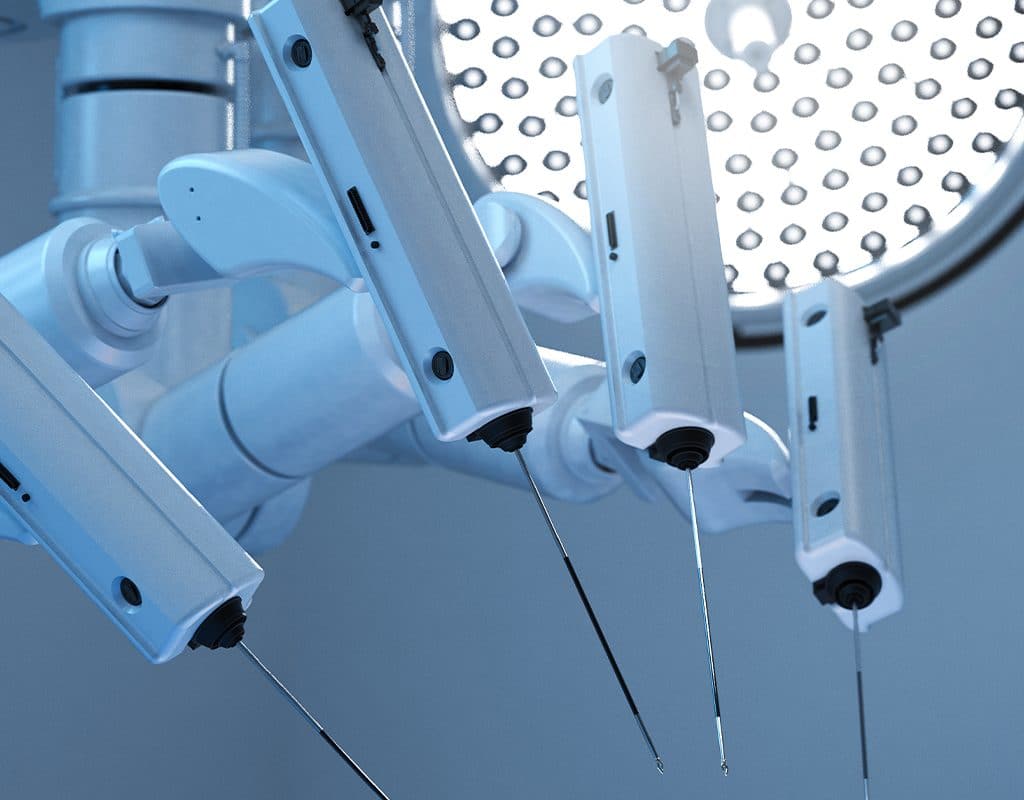

Medical

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

Defense

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

Cryogenics

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

Energy

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

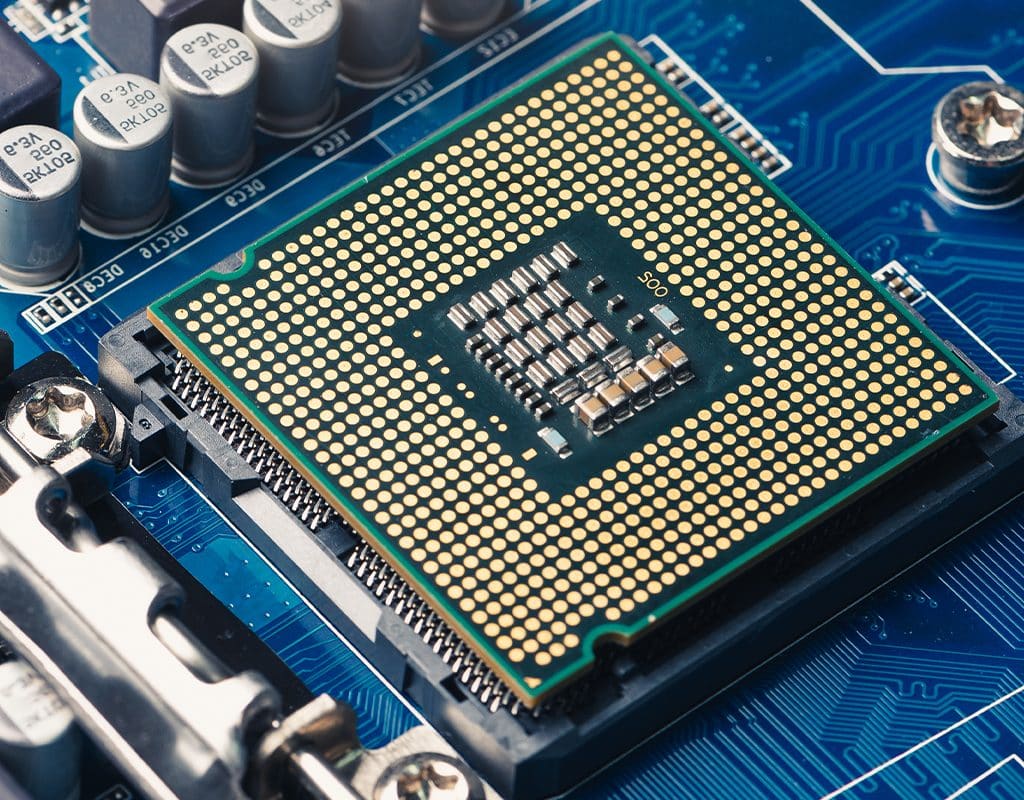

Semiconductors

Industries

You can count on Cattin to walk the path of excellence with you. Our rigorous processes and exacting standards create a solid framework for meeting the unique requirements of even the most demanding industries—including yours.

Radiostronomy

Machine tools

Aerospace

Aeronautics

Medical

Defense

Cryogenics

Energy

Semiconductors

Radiostronomy

machinable materials

At Cattin, we offer precision machining of a wide range of materials, including the most advanced.

15%

COPPER

BRONZE

BRASS

MACHINABLE AND CONDUCTIVE COPPER, BRONZE, AND BRASS

“Red metal” alloys containing copper, bronze, and brass are prized for their conductivity, making them ideal for a wide range of electrical and thermal systems. Their exact properties depend on the alloying elements used.

MACHINABILITY:

Very machinable

MAIN CHALLENGE:

Metal swarf—another word for shavings—is the main challenge when machining red metals. Choosing the right tool will ensure that the material removed from the part does not accumulate during machining.

20%

ENGINEERED

& REINFORCED

PLASTICS

AMAZING ENGINEERED AND REINFORCED PLASTICS

The engineered and reinforced plastics family is large and diverse. These materials—

ABS, PE, PETP POM-C, POM-H PEEK, PVDF, PMMA—offer a wide range of advantages. So, it’s no surprise that they are used in such a wide variety of industries.

MACHINABILITY:

Can be tricky

MAIN CHALLENGE:

Although engineered and reinforced plastics appear to be easy to machine at first glance, these complex materials do expand—sometimes a lot—and tend to have high moisture regain. Materials like fiber-reinforced plastics can also be very abrasive, creating additional machining challenges.

All machining parameters need to be precisely calibrated—even more so for micromechanical components. Deburring can also be more complicated than meets the eye. Which is where our experts come in.

20%

TITANIUM

TOUGH-AS-NAILS TITANIUM

Not only does titanium punch high above its weight in terms of strength, it is also biocompatible. This lightweight, durable metal plays a starring role in many industries today.

MACHINABILITY:

Difficult

MAIN CHALLENGE:

Titanium’s low thermal conductivity means that heat accumulates in the machining tool, causing the cutting edge of the tool to get hot, which in turn creates a very real risk of cracking. Plus, the material’s high strength-to-weight ratio requires high cutting force. Combined, these factors cause excessive wear and tear on cutting tools and can be detrimental to the repeatability of the machining process.

20%

STAINLESS

STEEL &

INCONEL

STAINLESS STEEL, INCONEL ®, AND SUPERALLOYS

Stainless steel and Inconel ®—both superalloys—are metals of choice in virtually all industries. More expensive Inconel® alloys, which are nickel-based, generally offer the same advantages as iron-based stainless steel, only better!

MACHINABILITY:

Difficult

MAIN CHALLENGE:

Inconel® alloys are highly ductile, which means that they are very resistant to cracking. However, it also means that they are much more likely to adhere to tools than stainless steel alloys. Inconel® alloys also do not conduct heat very well, which results in higher cutting forces and temperatures, both detrimental to process reliability tool lifespans. Drilling Inconel® alloys is particularly challenging.

25%

ENGINEERED

ALUMINUM

LIGHTWEIGHT ENGINEERED ALUMINUM, FAST AND EASY TO MACHINE

Engineered aluminum is lightweight and corrosion-resistant, with a long-lasting color. It can be cast, formed, and machined using a wide variety of techniques. These qualities make it one of the most commonly-used metals in a wide range of industries.

MACHINABILITY:

Fast & easy

MAIN CHALLENGE:

Metal swarf—or shavings—that build up on the tool surface is the main challenge when machining aluminum. Removing excess material from the tool and reducing friction are crucial. This metal is fast and easy to machine—but expert knowledge of the right parameters is needed to achieve the desired degree of precision.

a passion for precision

work with us

We are excited about a world in constant innovation.

And proud of our origins and history.

Be part of the next chapter.